Creating Turnkey Audio Solutions with ICEpower

Partnering with ICEpower on turnkey product creation helps you reduce operational complexity and lets your company focus on what truly matters – customers.

As an outsourced product creation partner, we take on projects from product ideas through development, certifications, ramp-up, manufacturing, and product maintenance of your products.

Learn More

Creating Turnkey Solutions Together

Why work with ICEpower on a Turnkey Basis?

Often companies tend to forget the total sum of resources put into developing, maintaining, and managing a product throughout its lifetime.

At ICEpower, we offer turnkey cradle-to-grave product creation management, taking care of everything from development to production and beyond. We understand that developing and managing a product throughout its lifetime requires significant resources. This often results in companies spending more time and energy on practical issues instead of growing their business.

We work with many companies who have more product ideas than the bandwidth to develop and bring them to market. This can lead to missed opportunities and hinder their business’s growth potential.

That’s where ICEpower comes in. We take care of everything, from product development to production, redesign, maintenance, and negotiation with contract manufacturers. With ICEpower, you don’t have to worry about any of the practical issues that come with product creation management. This allows you to free up your R&D and operational resources to focus on your customers and market understanding.

The majority of our projects is within one of these categories

Box Build / Amplifiers

We develop and manufacture the complete product, including analog hardware, digital hardware, software/firmware, networking and mechanics.

Backplates for Speakers and Subs

We develop and design complete backplate solutions for powered speakers or subwoofers, including amplifiers, power supply, mechanics and control interfaces, DSP, and software.

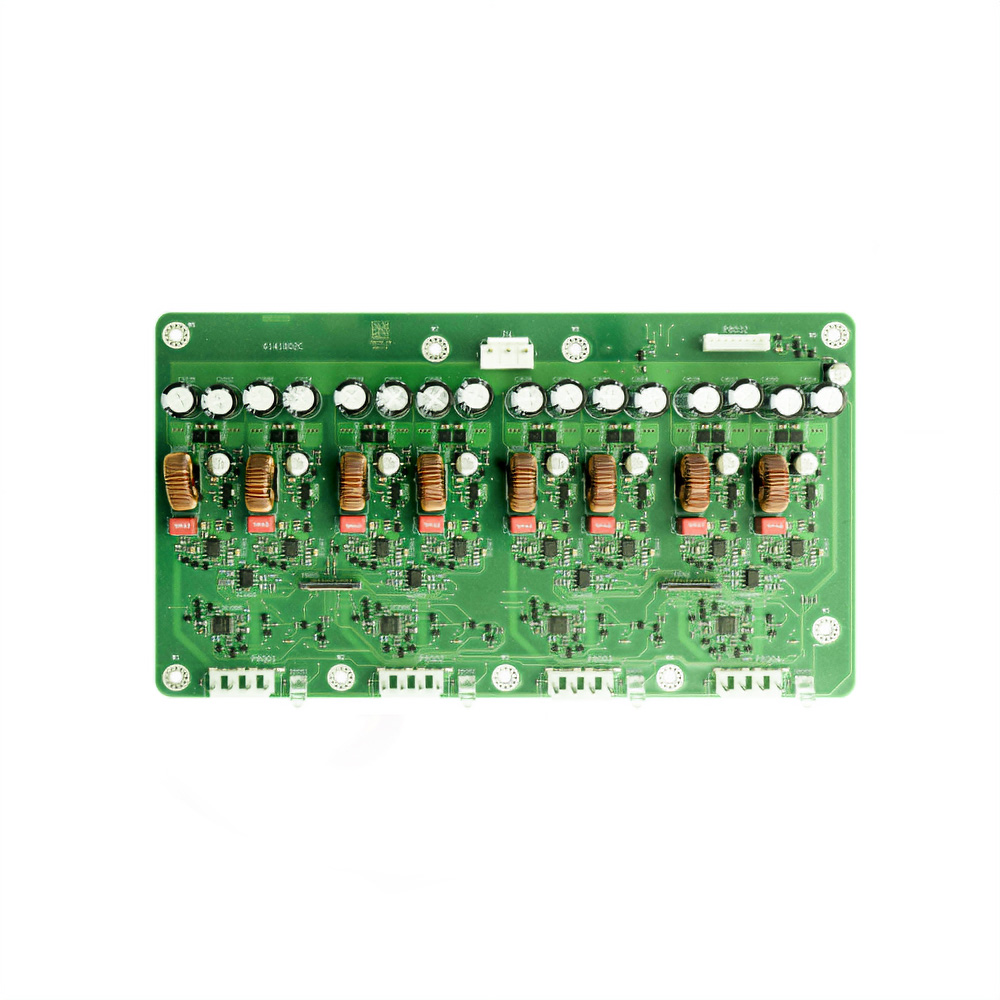

Custom Modules

We develop and supply customized PCBA modules, e.g. amplifiers, power supplies, digital front ends with DSP and/or network connectivity.

And within these three core application segments

Smart Home Audio

We provide a wide range of audio and power solutions for home automation. Including rack amplifiers, audio matrix switches, audio DSP processors, PoE amplifiers, wall panel controllers, network switches and other accessories,

Commercial Installation

Within commercial installtion, we can help you build best-in-class audio solutions for hotels, restaurants, educational facilities, and much more.

Professional Audio Solutions

We deliver best-in-class audio solutions, including rack equipment and backplates for powered speakers for both touring and fixed installations.

Our dedicated Audio Solutions experts will also help you through the idea generation and solution scoping process.

We have a dedicated team of Audio Solutions Specialists that supports you with your audio solution needs. This is to ensure that your product dreams come true. We want to make our knowledge available to you to ensure you get the amazing solutions you need to further your business.

We can take on all aspects of product creation from the cradle to the grave

By freeing up your R&D and operational resources you not only save money. It reduces your business complexity and enables you to focus on what matters most – your customers and your market understanding.

Idea Generation

With our 20+ years of experience in the audio industry, we can provide sparring and insights across multiple segments of the audio industry. What market segments and product categories are experiencing the most attractive growth, and what are the trends?

Scoping

With a deep understanding of the market, we can help provide input, suggestions, and sparring regarding product definition and features, thus helping create the product specifications. Based on our broad range of existing technology platforms, we provide advice and suggestions in architecting your product and selecting the optimal platforms. This also includes preparing accurate cost estimations based on actual BOMs.

Development

Once specifications are locked-in and we have official project kick-off, we will assign a development team and project manager to execute your project. This includes schematic design, layout, mechanical design, software development, etc. Over the years, we have honed our skills and tools in designing for cost, achieving the required performance and features at the lowest possible cost. We know well how to design for reliability and quality, designing with proper component de-rating and margins as well as including monitoring and protection systems of critical parameters such as temperatures, current, voltage, etc.

Validation

Once we receive the first prototypes, we spend significant efforts on verifying performance, functionality, and reliability. Our long experience in the audio industry means we know the use cases and stress products experience in the real world. This knowledge is built into the test and validation plans, ensuring we test for all the tough use case scenarios we know can cause trouble in the real world. Our testing also extends to compliance testing for safety and EMC, obtaining the required certificates. Our NPI team takes care of managing prototype builds, sourcing parts for mass production ramp up as well as creating mass production tester fixtures. We have developed our own advanced, standardized functional tester bases. This makes it a quick and relatively low-cost process to create individual test fixtures and test software for each specific product and PCBA.

production

Once released for mass production, our operations team will manage all supply chain aspects throughout the lifetime of the product. This includes forecasting, production planning, managing critical and unique components and suppliers, dealing with deviations, optimizing yields as well as ongoing price negotiations with suppliers.

Maintenance

Many of the products we provide to our customers have expected product life cycles of 10+ years. During this period, it often happens that components go End-Of-Life or become hard to source. It also happens that new safety and EMC standards are introduced. In such cases, we re-design and qualify alternative parts. We also monitor field failure rates and perform RMA analysis, taking corrective actions if issues are detected.

End of life

When the product nears its end of life, we work closely with your sourcing or product management team to manage the ramp-down process to minimize excess inventory and component liabilities.

Large catalog of Tech Platforms and IP

ICEpower has the biggest, most complete collection of Audio Platforms in the industry ranging from 1W to 7kW, and includes advanced features such as networked audio, Dante, AVB/Milan, DSP algorithms, GUI control, Power-Over-Ethernet, etc.

We have existing IP assets within most software for audio – including control based on proprietary protocols or industry standards like OCA, SNMP, etc. We do a lot of Audio over IP products every year, e.g.,, Dante, and we are a member of AVNU/Milan – doing an increasing number of AVB/Milan-based products. We also do PoE, PoE+, and PoE++.

We understand that no two customers or projects are the same. We are, therefore, flexible in our approach to collaboration. We can work with you on an end-to-end turnkey basis, where we develop and manufacture the complete solution, or we can do joint development (JDM), where either you or a 3rd party develops parts of the product.

Our platforms are continuously refined, improved, and new technologies are added. This means that most audio customers will find already working platforms that fit their applications.

These mature platforms enable us to quickly and cost-effectively develop the optimal solution for each specific customer application.

This gives us a head start as we are not starting from scratch with a blank sheet of paper. This enables us to provide you with better performance at a competitive price and a short development time.

World-class engineering expertise

We have deep expertise across the signal chain, extensive resources, and a strong team of engineers covering the following disciplines.

- Analog Hardware and switch-mode power electronics

- Digital Hardware

- Software incl. Embedded SW, FW & DSP, and Networking for audio

- Mechanics

- Project Management

- New Product Introduction (NPI) incl., test development, and compliance certification

The majority of ICEpower’s 75 engineers are working on specific customer projects, i.e. a full turnkey product and/or customer-specific custom solutions. All development takes place at our HQ in Copenhagen, Denmark, although we are little by little adding local R&D satellites to accommodate talented engineers at other locations in Europe.

Denmark is a ‘hub’ for audio. Power electronics is a core competence. With more than 200 audio companies and several Technical Universities and Engineering Educational Centers in Denmark focusing on software and power electronics for audio, ICEpower could not be better located and positioned for developing electronics for audio. It is an ideal environment for continuously adding more talented Audio Engineers to our R&D team.

We are proud to state that ICEpower is a Center of Excellence in audio hardware and software today.

Strong Project Management and Execution

ICEpower is a lean, no BS, project-focused organization. We have developed project management and project execution into a core competence. According to many of our customers, it might actually be the most essential competence today.

Having a clear R&D project focus enables us to execute projects efficiently and fast. Typical project execution is from 10-18 months from kick-off to mass production, depending on complexity. We work with a structured stage-gate development model with a focus on design reviews. We set project KPI’s which we track and review on a monthly basis. A project is a long-term and complex engagement. We believe that a win-win partnership mindset, trust, transparency, and frequent and clear communication are crucial to success.

We arrange weekly or bi-weekly project meetings with our customers. When kicking-off projects with a first-time customer, our entire project team will usually visit your corresponding team to build the mutual understanding and relations important for a smooth collaboration throughout the project.

Robust and cost-efficient Supply Chain

ICEpower works with SVI and GPV in Bangkok. It is a deliberate decision to work with mid-size EMS Companies. SVI and GPV are focused on high mix / low-medium volume production and have Danish management. We have strong long-term relationships with their top management, which ensures attention.

ICEpower has good pricing power as we have high volume (for the audio industry). We actively engage in category management, building relationships, and negotiating directly with all key components and materials suppliers.

We have selected Thailand due to several reasons:

- Access to skilled labor and tradition for longer-term employment

- Competitive cost level compared to other typical “low cost” countries

- Politically stable location

- No tariffs when importing to the US

Having a dual manufacturing setup improves our supply security. It also enables us to ensure competitive quoting processes, always having at least two suppliers provide a quotation.

Our dedicated S&OP team is in close daily contact with both suppliers, providing support and ensuring a structured forecasting and planning process.

Managing Costs

Our extensive portfolio of proven platforms enables ICEpower to create concepts based on an 80-90% costed BOM. This means we have a good handle on cost already at the concept stage before we kick off the project.

This continues during the project as we make a costed BOM rollup at every design milestone with current BOM on all subassemblies to ensure all design parts are within target costs.

We track all changes to the design requirements to give complete visibility on cost impact towards our customers.

Our engineers are skilled in careful and cost-effective component selections based on our existing parts database, purchasing volumes, prices, component lifecycle, and our and/or our supplier relationships.

Design Quality

• Use of proven ICEpower platforms

• More than a 1000 years of combined ICEpower design experience in audio

• Focus on design reviews

• Structured approach to design verification with test checklists

• UL certified products

• Reliability testing

Manufacturing Quality

• Good workmanship

• Proprietary ICEpower manufacturing test setup

• Remote yield monitoring

• Full tracking of all products

• Burn-in capability

• Product maintenance team

Don’t hesitate to reach out!

Do you want to have a custom audio solution created that matches your needs?

Developing your next Turnkey Solution is an exciting project and working with ICEpower secures a smooth process.

We have extensive experience in creating high-quality solutions for some of the largest brands in the world.

Once we have received a briefing on your project and requirements, we will deliver a complete project scope with solution architecture and timing plans.

Stay Up To Date With ICEpower

Be the first to hear about our new products, workshops, events, contests and more.